We have the best results thanks to advanced technologies and the last generation equipment.

EXPERIENCE AND TECHNOLOGY

Meccanica Rhodense is able to design specific components for any use; is able to guarantee the realization of drawings relating to supply of products using CAD techniques and certification documentation and quality analysis using effective and tested procedures.

WE ANALYZE THE CONTEXT TO PROPOSE THE BEST SOLUTION

Context analysis is fundamental for defining the tools and methods aimed at achieving the objective. The comparison in team and the careful analysis that our engineers refer to the single project, allow in fact to develop and propose the best products for every destination of use.

WE PROCESS IDEAS OPTIMIZING THEM THROUGH OUR KNOW HOW

Thanks to the know-how acquired in decades of experience, to the accurate analysis of the reference context and to the latest generation software, we are able to design what is proposed, analyzing any critical issues in compliance with the specific need and always seeking innovative production processes and can be integrated with each other. Competence, Experience and Quality are the words that best describe us and are reflected in all our realization.

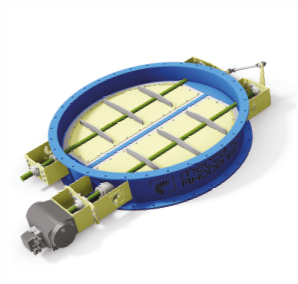

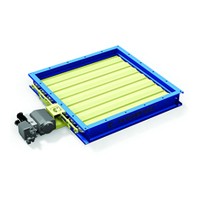

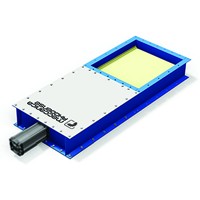

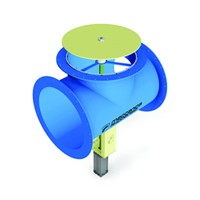

WE REALIZE UNIQUE, RELIABLE AND PERFORMING MANUFACTURES

Thanks to the know-how and professionalism of our engineers and our staff, we create projects for high-performance products using the best technologies and innovative proven manufacturing techniques.

WE TESTING INTERNALLY EVERY PRODUCT WITH THE BEST TESTING TOOLS

Meccanica Rhodense guarantee the declared performance of each product thanks to a internal testing area. In fact, the conclusion of the project involves an accurate test phase using the most modern testing tools to ascertain the quality and performance of the final product.

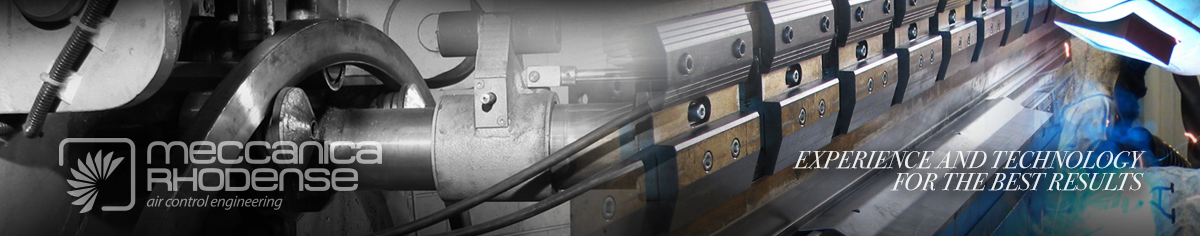

EQUIPMENT

All production activities are carried out using specific machinery for laminate processing.

All production activities are carried out using specific machinery for laminate processing. All semi-finished components made internally are transformed with maximum precision procedures guaranteed by the high technology of the machines:

Tutti i componenti semilavorati realizzati internamente vengono trasformati con procedure di massima precisione garantite dalla elevata tecnologia dei macchinari:

- CNC automatic punching machine

- CNC 6-axis bending machine

- CNC linear cutting machine

- Electronic positioning shears

- Pulsed arc welders